Additive Manufacturing – thinking things new.

Additive Manufacturing (AM) is the process of manufacturing objects from Computer Aided Design (CAD) model data, usually layer upon layer, as opposed to using methods of subtractive manufacturing (removing material until the desired shape is reached) or formative manufacturing (applying mechanical forces and/or heat through processes such as bending, casting, and molding).

FROM CONCEPT TO COMPONENT

As a global steel and technology leader, we offer the full suite of production techniques and services throughout the value chain, supporting and driving innovation and development based on lengthy experience around materials and processing. Starting from the alloy development and metal powder production, to design and manufacturing and including post-processing. We offer the end-to-end solutions to reduce waste and mitigate risk in the supply chain with the goal of being your trusted and reliable business partner. We deliver tailormade solutions from concept to component.

| Metal Powder |

|

|

|

|

Parameter Development |

| Design/Simulation |

|

|

|

|

Additive Manufacturing |

| Heat Treatment |

|

|

|

|

Machining |

| PVD Coating |

|

|

|

|

Inspection/Testing |

FLEXIBILITÄT UND KOMPETENZ

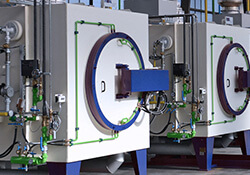

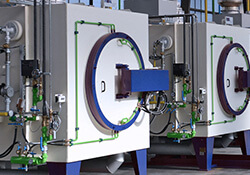

The Centers of Excellence use equipment from leading AM production equipment suppliers for both laser beam melting and laser metal deposition. By working with both production technologies from different equipment suppliers, voestalpine has the flexibility and expertise to select the best AM production process for your application.

|

|

| Laser Beam Melting |

Laser Metal Deposition |

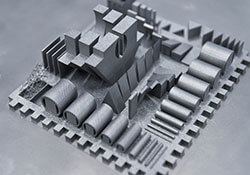

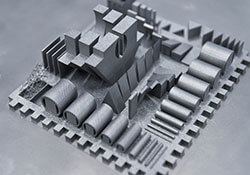

LIGHT WEIGHT

With the added freedom of additive manufacturing design, additional shapes and connectivity of multiple parts can be explored. Additive Manufacturing allows highly optimized fabrications designed for the best results in terms of weight and stability.

COMPLEXITY

AM offers a new way of producing parts in nearly endless forms and complex structures which solves problems e.g. in molding production. That’s why applications in the tooling industry are showing big potential for AM.

EFFICIENCY

Additive Manufacturing can drive efficiencies because AM is able to produce near net-shape parts.

Download our brochure: Additive Manufacturing

Here you can find out everything about our powders for Additive Manufacturing:

Find out more on our microsite for Additive Manufacturing.